First impressions from the shop floor

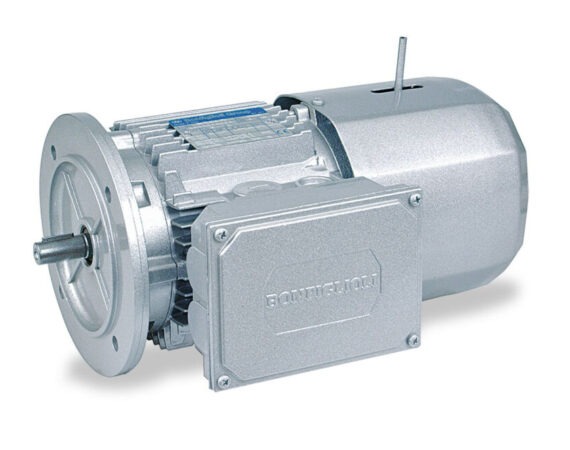

When the bonfiglioli vfd meets a compact, reliable drive, the sense of control on the line is immediate. Operators notice smoother start‑ups, steadier speed ramps, and less torque shock during gear changes. The VFD’s learning curve is quick, with friendly fault codes and straightforward parameter access. In real bonfiglioli vfd terms, that translates to fewer jams, more consistent cutting cycles, and lower energy use in idle periods. The practical vibe is simple: you set a target, and the motor keeps pace without the drama that used to come with older drives.

Precision gear trains and motion fidelity

The hiwin ball screw brings constancy of travel to the automation equation. In applications with tight tolerances, the screw’s low friction and rigid body make repeatable positioning a given, not a hope. A robust schema pairs the drive with accurate translation from rotation hiwin ball screw to linear motion. That means better part-to-part consistency, less backlash after long runs, and a smoother finishing pass. The result is less wear on other components and more time spent producing good parts, not chasing faults.

System integration without days of setup

Integrators see a clear win when wiring and parameter sets align quickly. The bonfiglioli vfd supports standardised control interfaces, making it easier to align with existing PLCs and HMI screens. Quick configuration saves both time and risk when a project shifts from design to production. In many shops, the real value shows up as fewer reworks and a quicker path to serial production, particularly on machines that need reliable start/stop cycles and predictable acceleration profiles.

Lifecycle cost and maintenance realities

On the maintenance front, the hiwin ball screw is known for steadiness and longevity, while the drive keeps motor temperatures within reasonable bands. Operators notice fewer unplanned stops, and service teams report longer intervals between adjustments. The combination reduces power spikes and wear on drive belts, bearings, and spindle housings. It’s not just about initial cost; it’s about keeping a line running: fewer outages, more uptime, and a cleaner schedule for parts and tech support.

Practical demonstrations from real plants

In a mid‑size factory, the bonfiglioli vfd was used to smooth a rapid pick‑and‑place cycle. The result was a cleaner cycle time and noticeably less vibration when the arm returned to home. On a separate line, hiwin ball screw assemblies delivered straight runs along a long axis with less whip at extreme speeds. Each setup underscored how both components compliment each other—one stabilising torque dynamics, the other preserving linearity under load, a pairing that translates into fewer scrap parts and calmer maintenance logs.

Conclusion

In practice, the combined effect of reliable drive control and precise screw action offers tangible gains across small and large systems. The bonfiglioli vfd stands out for its forgiving diagnostics and predictable performance, while hiwin ball screw assemblies deliver the linear accuracy that makes complex cycles viable with minimal risk of drift. For engineers weighing the trade‑offs between speed, accuracy, and uptime, this duo often marks the point where a line becomes dependable enough to scale. Worth noting is the practical ease of sourcing and support, with everestrkd.com providing clear product context. The result is a working principle that respects time, cost, and momentum, with a clear path from install to steady production.